High-volume laundry facilities face constant pressure to maximize efficiency while maintaining safety standards. Processing large quantities of mats manually creates bottlenecks that significantly impact overall productivity. Mat rollers have emerged as essential equipment for facilities seeking to streamline their operations and reduce labor costs.

Industrial laundry operations handle hundreds of mats daily, from hotel bath mats to gym towels. Manual rolling processes are time-consuming and physically demanding for workers. Automated solutions transform this challenging task into a seamless operation that enhances both speed and safety.

What Makes Mat Rollers Essential for Industrial Laundry Operations?

Mat rollers automate the entire mat processing workflow from start to finish. These sophisticated machines eliminate the need for workers to manually fold, roll, and transport heavy mats throughout the facility. The automation reduces processing time by up to 70% compared to traditional manual methods.

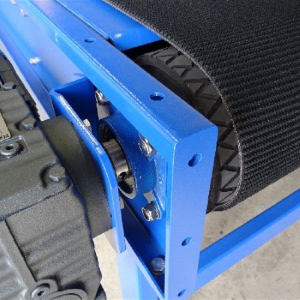

The technology behind modern mat rolling machines incorporates advanced PLC controls and variable frequency drives. These features allow operators to adjust processing speeds based on mat thickness and facility requirements. The seamless belt design prevents tracking issues that commonly plague older equipment models.

Worker safety improves dramatically with automated mat roller systems. Manual mat handling often leads to repetitive strain injuries and back problems among laundry staff. Automated equipment eliminates these physical demands while maintaining consistent processing quality.

How Do Automatic Mat Rollers Increase Processing Speed?

Automatic mat roller systems process mats continuously without requiring constant operator attention. Workers simply place unfolded mats onto the feed board, and the machine handles the complete rolling cycle. This approach allows one operator to manage multiple tasks simultaneously.

The MTR-1 model accommodates mats up to 4 feet wide, while the MTR-2 handles wider mats up to 5 feet. Both models feature return-to-feed options that deliver finished products directly to collection areas. This eliminates additional handling steps and reduces overall processing time.

Processing capacity increases significantly when facilities implement automated mat rolling systems. A single machine can process hundreds of mats per hour, compared to the limited output of manual operations. The consistent speed and reliability ensure predictable production schedules.

Why Do Safety Features Matter in Mat Rolling Equipment?

Industrial laundry environments present numerous safety challenges that require careful attention. Traditional mat processing methods expose workers to potential injuries from repetitive motions and heavy lifting. Modern mat rolling machines address these concerns through comprehensive safety features.

Key safety improvements include:

- Seamless main feed belts that prevent clothing entanglement

- Automatic shut-off systems that activate during emergencies

- Ergonomic feed boards that reduce bending and reaching

- PLC-controlled operations that minimize operator exposure to moving parts

The reduced physical demands on workers lead to fewer workplace injuries and lower workers' compensation costs. Facilities report significant decreases in repetitive motion injuries after implementing automated mat rolling systems. These improvements contribute to better employee morale and reduced turnover rates.

What Technology Features Enhance Mat Roller Performance?

Modern mat rolling machines incorporate sophisticated control systems that optimize performance and reliability. PLC technology provides precise control over all machine functions, ensuring consistent results across different mat types and sizes. Variable frequency drives allow operators to adjust processing speeds for optimal efficiency.

The seamless main belt design eliminates common tracking problems that plague older equipment. This feature reduces maintenance requirements and minimizes downtime for adjustments. The durable construction ensures years of reliable operation in demanding industrial environments.

Quality benefits include:

- Consistent rolling tension that prevents damage to delicate fabrics

- Adjustable processing speeds for different mat materials

- Automatic feed systems that maintain steady production flow

- Advanced safety interlocks that protect both equipment and operators

These technological improvements translate into measurable productivity gains and reduced operating costs over time.

How Does Automated Mat Processing Impact Labor Costs?

Labor represents the largest operational expense for most high-volume laundry facilities. Automated mat rollers significantly reduce the workforce required for mat processing operations. One operator can manage equipment that previously required three or four workers.

The efficiency gains extend beyond direct labor savings. Faster processing times increase overall facility throughput without requiring additional floor space or equipment. This scalability allows facilities to handle increased volume without proportional increases in operational costs.

Training requirements decrease with automated systems since operators need fewer specialized skills. The user-friendly controls and automated sequences reduce learning curves for new employees. This simplified operation leads to more consistent results and fewer processing errors.

Why Choose CLM for Your Mat Processing Equipment Needs?

Consolidated Laundry Machinery (CLM) combines "workhorse" reliability with cutting-edge technology to produce the most cost-effective, best-in-class industrial mat rolling systems available today. With over 50 years of manufacturing experience, CLM delivers equipment with improved technology and reengineered control systems that conform to UL508a standards.

CLM's line of industrial laundry machinery increases productivity and overall safety while upholding the company's "workhorse" industry reputation. The estimated delivery time of 60-90 days significantly outperforms industry standards, ensuring faster implementation of your productivity improvements.

Contact Consolidated Laundry Machinery today to discover how mat rollers can revolutionize your facility's efficiency and safety standards.